Quality Control

Quality is constant

Diligence, processes, and attention to detail are at the core of our business. Our operational framework is built on the 4Cs:

four pillars of quality that underpin our role as the world’s leading display panel designer and manufacturer.

four pillars of quality that underpin our role as the world’s leading display panel designer and manufacturer.

Comprehensive

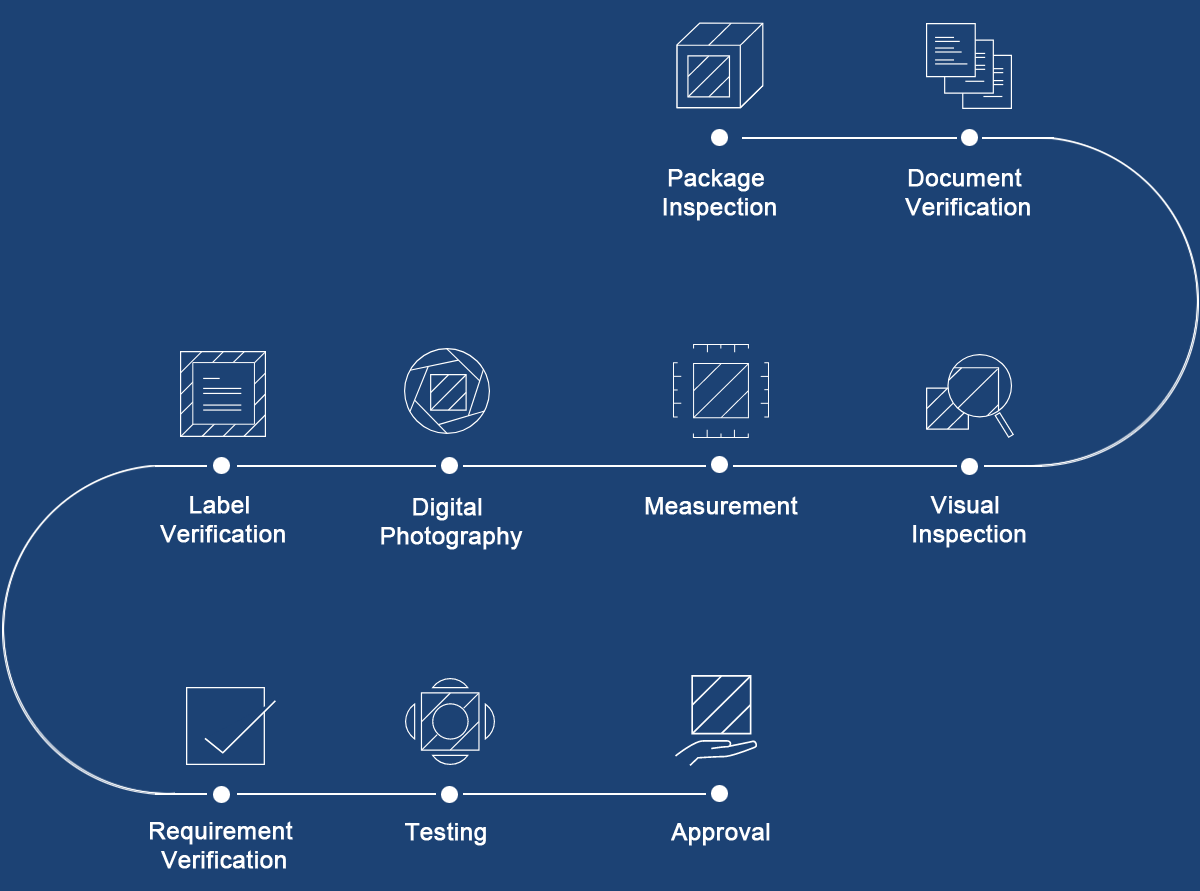

We maintain keen attention to detail in everything we do, from how we qualify and manage our suppliers to how we package and deliver products. Our systems-based inspection process ensures electronic components meet our exacting standards.

Consistent

Even as we grow, We stays laser-focused on quality. We follow defined processes and procedures precisely to continually replicate high-quality results and hit the target each and every time.

Continuous

We never stop striving. We always innovating new and better service offerings, training employees for continual growth, and upgrading facilities to stay on the cutting edge of technology.

Certified

It’s not enough to meet quality expectations – we exceed them. We actively maintain third-party certification requirements and reach beyond those standards to promote the highest level of quality in our products and services.Our inspection process reflects our systems-based approach to

quality

We inspect, measure, verify, and test electronic components from the outer packaging inward to confirm that they meet the highest standards. This process is thoroughly documented in proprietary operational platform. Any team member around the world can access this information, ensuring operational consistency and unwavering customer support.

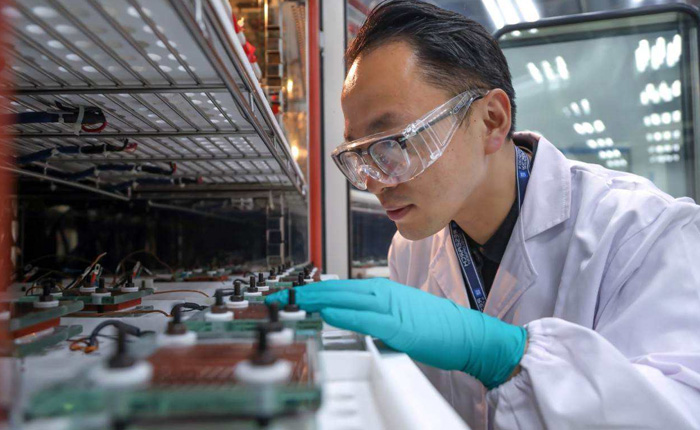

We are committed to the quality of every product we source

Our highly trained quality inspectors stay up to date on the latest in fraud and counterfeit detection and prevention. Our inspection process will exceed your exacting standards.

Our maintains strict environmental controls at our three global operational facilities.

We protect your products across all stages of the supply chain.

We protect your products across all stages of the supply chain.

Our people go above and beyond to ensure the quality, authenticity, and security of your components.

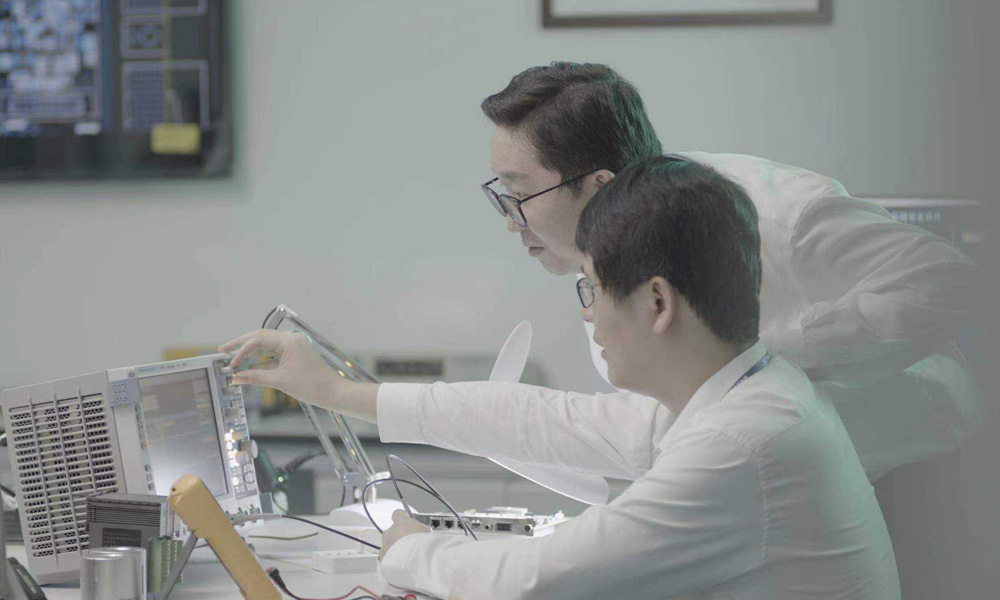

Our testing and inspection process requires careful attention to detail and extensive industry knowledge. Our quality inspectors are expertly trained to identify and avoid faulty and suspect parts. All of us inspectors are certified to the CCCI-102 standard for product inspection and counterfeit mitigation. This certification ensures that our quality team is trained to safeguard and effectively examine components.

Our quality control department inspects, tests, and verifies the gamut of electronic components. Our quality engineers provide the technical expertise necessary to determine the optimal testing techniques for each component type, perform root-cause analysis, and continually improve our operational efficiency.

Our quality is rooted in more than processes and certifications.

Our people are another of our greatest resources in our drive for continual excellence. Third-party accreditation programs and our proprietary training curriculum work together to provide our employees a wealth of industry and quality knowledge. Our global operations employees are required to renew annual trainings on topics ranging from MSL and ESD compliance to counterfeit mitigation and cybersecurity so they can ensure products and services meet the highest standards.

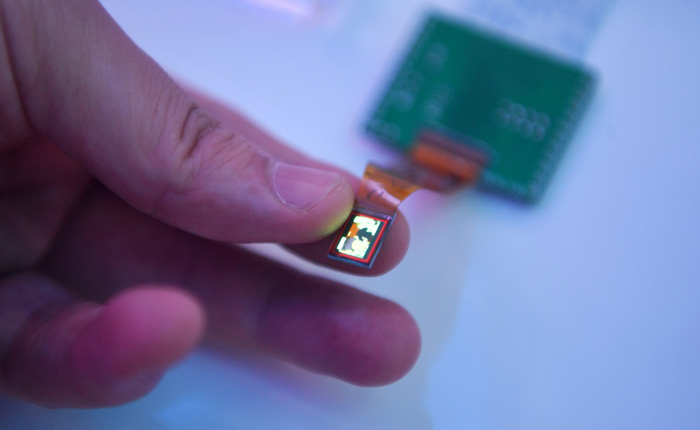

Functionality Testing

Our functionality lab can test the full range of electronic components and peripherals to ensure they are fully functional.

We offer a range of tests to determine components’ quality, capacity, output, value, and more.

We offer a range of tests to determine components’ quality, capacity, output, value, and more.

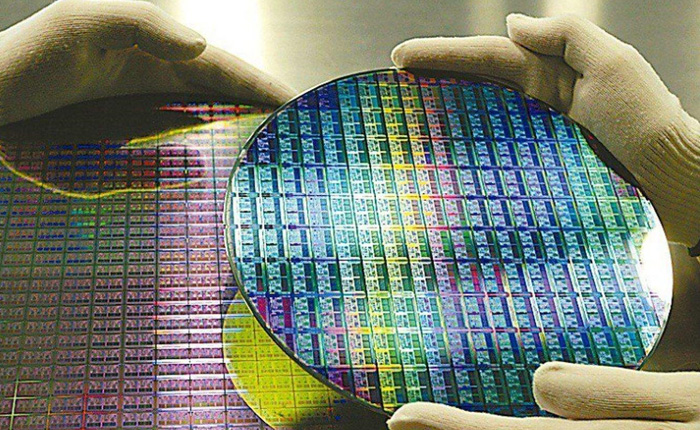

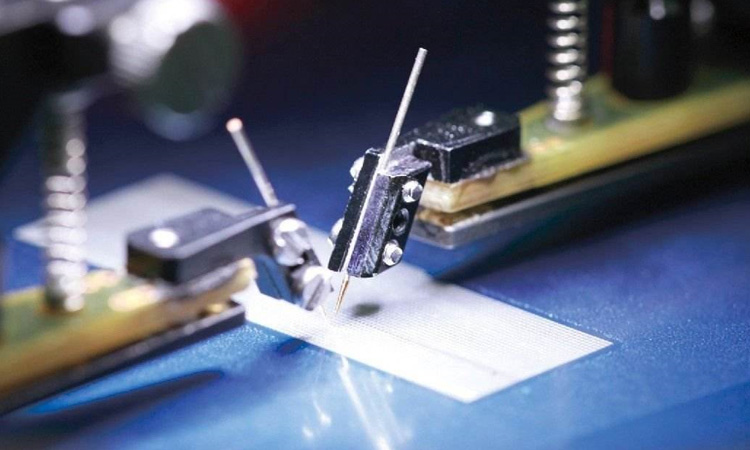

Authenticity Testing

Our counterfeit detection testing lab is provisioned with the most advanced in-house tools to verify component authenticity.

With destructive, nondestructive, and custom testing solutions available, the integrity of your parts will never be in question.

With destructive, nondestructive, and custom testing solutions available, the integrity of your parts will never be in question.

Custom Testing

We offer custom functionality testing for components and consumer electronics, from full-unit to component-level.

As grows, we continue to expand our testing capabilities so we can continue to meet your most stringent requirements.

As grows, we continue to expand our testing capabilities so we can continue to meet your most stringent requirements.